Every day, there are risks to your supply chain–from more visible problems like the global pandemic and the war in Ukraine to a shifting labor market to natural disasters, import/export policies, and local labor challenges. Supply chain risks can come from any direction, up to and including loss of suppliers and diminished carrier capacity.

Want to withstand many possible and very real disruptions and prepare your company for the future?

Until recently, planning scenarios–an essential element of supply chain design–were often neglected due to the processing-power limitations of desktop-based solutions. And building dozens of scenario variations to test different changes was cumbersome.

But better supply chain planning, business decisions, and outcomes are entirely possible when you ID your visible and less-visible supply chain risks to avoid sourcing and inventory issues but also address systemic risks that might vary based on the network’s structure.

What is Risk Management?

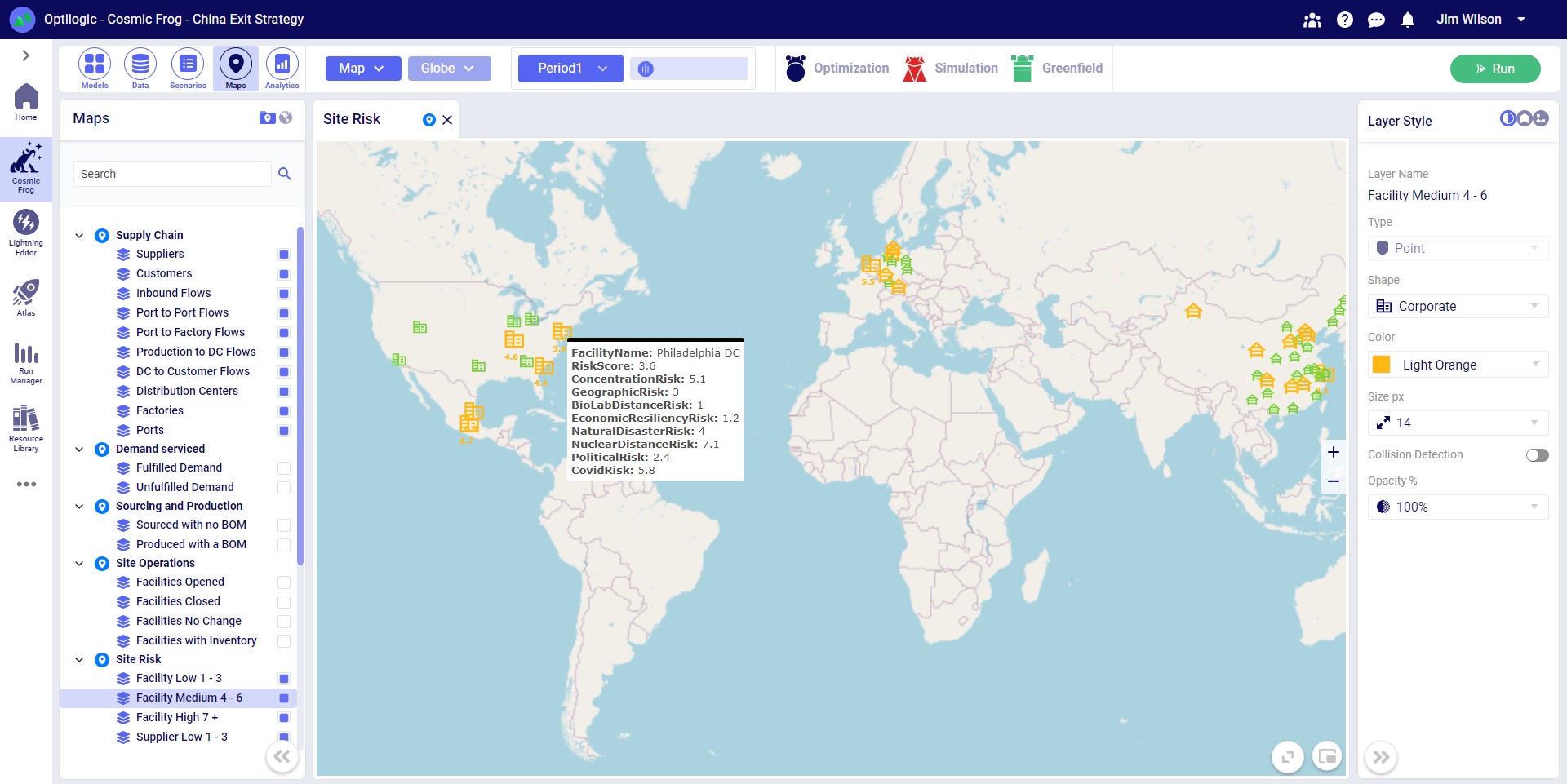

IDing and quantifying risk are modern ways to improve decision-making, efficiency, and risk management with earlier identification of potential risks that could transform into significant problems. Running scenarios allows your organization to visualize and evaluate options within your supply chain. Adding or removing constraints within various scenarios gives you access to data, enabling you to understand the cost, risk, and service outcomes that help guide your decision-making.

What is Sensitivity Analysis?

An integral part of the supply chain design discipline, sensitivity analysis allows users to understand how robust a scenario is when variables such as transportation costs and customer demand change. Designing a supply chain network that incorporates risk management requires running sensitivity scenarios–ideally using a platform that allows large-scale sensitivity analysis with a single click.

At Nexterus, we use sensitivity analysis to give you a clear sense of which scenarios will impact your supply chain. Our tool–Cosmic Frog–automatically generates sensitivity scenarios showing the impact on cost, service, and risk when transportation costs and demand quantities are adjusted by -15% -10% -5% +5% +10% +15%.

A sensitivity analysis:

- Can create a comprehensive supply chain model that considers all the essential components, suppliers, and/or production processes involved, as well as associated policies and costs.

- Uses the Opti-Risk score computed by Cosmic Frog for each facility and supplier to identify potential disruptions to your supply chain–including disruption recovery time, alternative suppliers’ availability, and customer impacts.

- Provides granular detail that shows the complexities and interdependencies of modern supply chains accurately, assessing the profit impact of each disruption by considering disruption costs, like lost sales, increased costs, and lost productivity.

- Prioritizes mitigation efforts based on the estimated profit impact of each potential disruption, allowing the organization to focus on the most critical risks first.

Optilogic Risk Management

Rather than relying on historical data, competitive trends, or instinct, Optilogic Risk Management’s scenario planning informs your choices, whatever scenarios you choose to analyze, whether you are:

- Considering right-shoring overseas manufacturing options or bringing manufacturing closer to your customer base

- Addressing expansions or contractions

- Determining where to optimize manufacturing and warehousing space

- Consolidating transportation options that reduce emissions

Understanding how taxes and duties impact your total cost-to-serve and your revenue so you can determine the best routes for product transport while achieving exceptional customer service - Exploring how you can bring your product closer to the last distribution segment and develop your last-mile strategy to ensure fast delivery regardless of customer location

- Exploring sourcing and network redundancy alternatives, like using two manufacturing locations to avoid supply chain disruption

Each time you run a scenario, you look for ways to optimize the supply chain. You can decide which is right for you–whether to optimize for cost, customer service, risk, or other business objectives like sustainability.

In today’s volatile market, businesses must ensure that if something happens within their supply chain (loss of supplier, loss of facility, carriers going out of business, merger/acquisition, and more), the business can continue to thrive. Nexterus takes a proactive approach to risk management to help clients identify risks within their supply chains. To mitigate risks, we run a scenario analysis and create a strategic plan to make your supply chain more agile and robust. Contact Nexterus today.